The COVID-19 virus is changing every industry in many ways. Globalization has helped us reach almost every home making the globe a huge marketplace. Unfortunately, COVID-19 is changing the game. While many countries rely on their allies to help with the supply chain, some countries are not able to continue manufacturing due to the population isolation as a consequence of the virus.

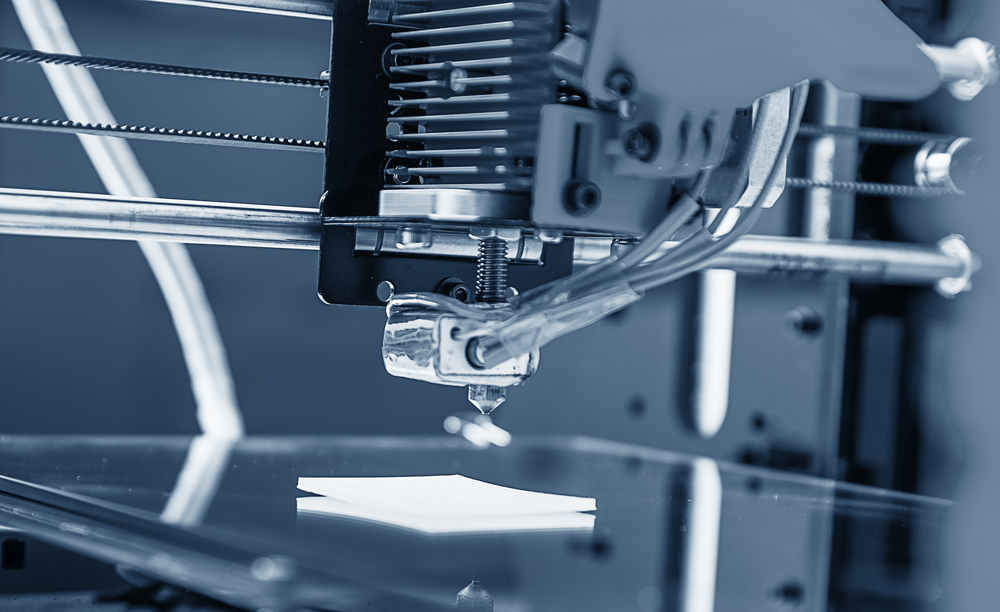

The need for local manufacturing is crucial these days. The new reality requires adaptation which, in turn, means that new technologies will have to be adopted faster than ever. In these hard times, 3D printing is the rising star and not science fiction anymore.

Local production –

As mentioned, globalization made the globe a terrific marketplace, but nowadays, every country needs to increase its local production to survive in these hard times. Additive manufacturing has become a great solution for spare parts. A good example is the use of additive manufacturing for medical device spare parts.

A group of Italian entrepreneurs has printed ventilator valves for hospitals. The valve cost was $1 compared to the $10,000 charged by the original manufacturer. Local production with the use of AM reduces costs, but it can also save lives in extreme times like these.

Reduce lead time –

The comparison between traditional manufacturing and additive manufacturing is one of the most talked-about subjects in the history of additive manufacturing. However, it is worth mentioning that additive manufacturing these days has become one of the greatest tools for on-demand spare parts manufacturing. While traditional manufacturing lead time can take a few days and even weeks, additive manufacturing reduces the lead time from a few weeks to a few hours. These extreme times are producing new applications for additive manufacturing, thereby enabling service providers to find new applications with the use of additive manufacturing to help hospitals with their increasing demand for new medical device spare parts.

Availability –

While worldwide shipping is currently not an option, and the demand for local manufacturing is growing naturally, we need to use one of the greatest strengths of additive manufacturing, the option to switch between jobs quickly. Even due additive manufacturing is not ready for mass production, the option to manufacture several different jobs at the same time, increase the availability for new applications and fulfill the hospital’s needs.

COVID-19 could be a huge opportunity for 3D printing service providers, 3D printing workflow solutions, etc. With new applications emerging every day, the manufacturing industry needs to embrace and leverage these changes to shape better manufacturing capabilities in the future.