This is a fascinating case of an industrial service bureau, which 3D prints spare parts for the Aerospace industry, somewhere in North America. They asked to remain anonymous so we will just refer to them as ‘The Client’.

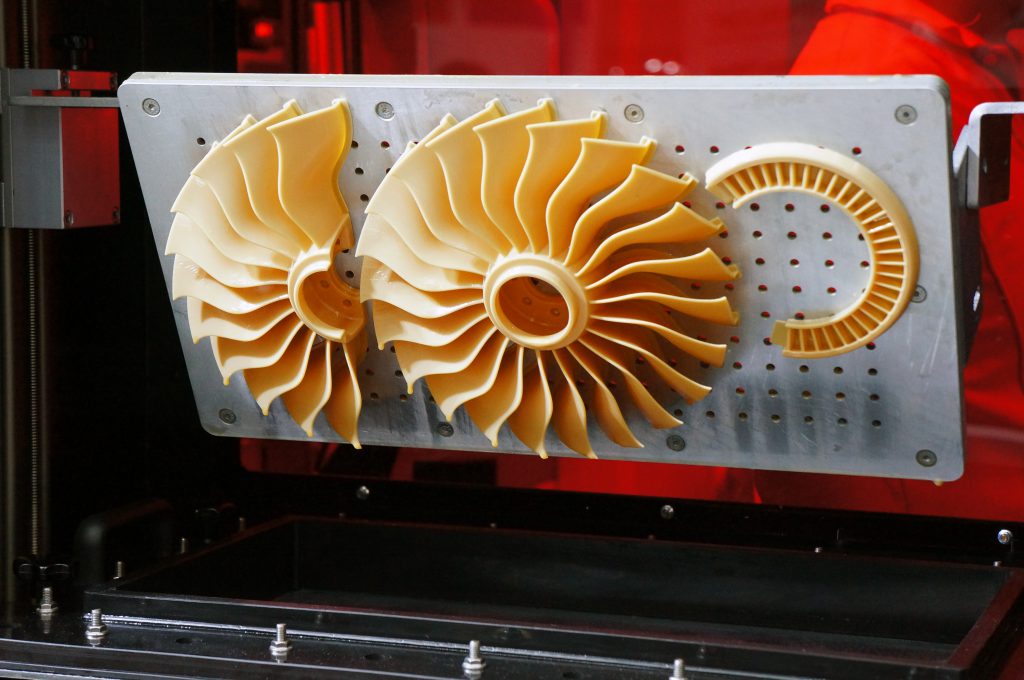

The Client has been in the manufacturing business since the mid 90’s and several years ago, they decided to add 3D printing to their business offering. Their 3D printing business leveraged from the technology evident advantages, specifically for markets like Aerospace. These advantages include, among others, the option to print complex geometries, reduce weight, being much more economical for prototypes and short serial production, etc. The Client further invested and today The Client uses two commonly available 3D printing technologies, FDM and SLS, and has a 5 printers’ shop.

Bottom line, the business grew nicely and now The Client prints on average 275 unique parts per month. Sounds great, no? The poor reality is that despite this impressive traction, The Client became a victim of his own growth.

THE CHALLENGE

The Client needed to scale up. He said:

“The more we grew, the more concerned I became with the actual production workflow, which is not scalable or efficient by any means. We spend too much time evaluating parts from our customers before they get printed. If we identify failure areas, we need to hold lengthy phone calls with our customers to put them on the same page. Too often we miss and print failed parts.”

The Client also needed to be freed up to run the business, not the day-to-day operations. He said:

“I, as the 3D printing business manager who established this operation in our company, have become the bottleneck for everything related to 3D printing. I spend too much time on queries about materials, about which technology should be used, about giving the correct price quotation for a part, etc. It is only getting worse since we added SLS to our FDM and grew the volume of parts.”

The Client summarized his needs in the following sentence:

“We need to create a more robust, scalable process that would support our sustainable growth”.

THE SOLUTION – Leveraging artificial intelligence in 3D printing with PrintSyst’s 3DP AI-Perfecter™

PrintSyst set itself on a mission to optimize, automate and turn reliable the manual, costly and time consuming pre-3D printing evaluation process.

PrintSyst founders, printing veterans, came to this conclusion after working hands-on in producing 3D printed parts for several years. They looked for a way to improve the success rate of 3D prints and to automate workflows. The company had developed an AI engine with unique algorithms and advanced machine learning capabilities: the 3DP AI-Perfecter™.

RESULTS

PrintSyst solution step changed The Client business’ financials. We will share some numbers in a minute. This was kind of expected, even though not to this extent. Otherwise, why bother?

Surprisingly, adopting an AI-based automation tool yielded additional unexpected positive outcomes:

- Improved customer experience of The Client’s customers, as PrintSyst’s solution improved the communication with these customers about the parts they sent to The Client. Communication became instant, visible and crystal clear in terms of expectations setting. Lots of frustration and miss communication issues have been eliminated, not to mention the customer support time saving.

- Scalable 3D printing knowledge management now enables the business manager- who is the 3D printing expert in The Client’s case – to spend his time more wisely, only on complicated edge cases. The rest of the workforce, mostly junior engineers, can now enjoy an instant expert’s guide using the 3DP AI-Perfecter’s printing recommendations.

- The business manager himself actually increased productivity as he is able to devote more time to managing the business and developing it.

Of course, there were cost savings and boosted profits;

Take a look at these impressive numbers, which sum up to more than $150K annual savings(!):

- Annual savings in time-consuming labor: $79,788

- Annual savings in failed prints: $58,995

- Additional profit from accurate Pricing: $19,868

In The Client’s own words “PrintSyst provided the robust, scalable process we needed to help us grow.”

Do you want to learn more how we might assist you? Please don’t hesitate to contact us.

WHAT TO EXPECT?

- Instant, automatic & accurate pre-printing part analysis

- Immediate ROI – 99% less preparation time

- Instant, customized to your needs 3D part price quotation

- Materials selection guide with advanced machine learning and customization capabilities

- Integrated production dashboard that creates instant visibility

- Simple to use software for any team member

- A path to a scalable, robust 3D printing workflow